DUT KOREA’s products are focused on operators and offers optimized production units.

The innovative technology on accumulation of experiences are supplied as high compatibility for the entire line then it gives you bigger competitiveness.

At this time we can propose you the following items:

- CAR SEAT LINE (Oval Conveyor)

- CAR SEAT LINE (Turn Table)

- CAR SEAT LINE (Turn Table)

Details here under

Do not hesitate to contact us for more information

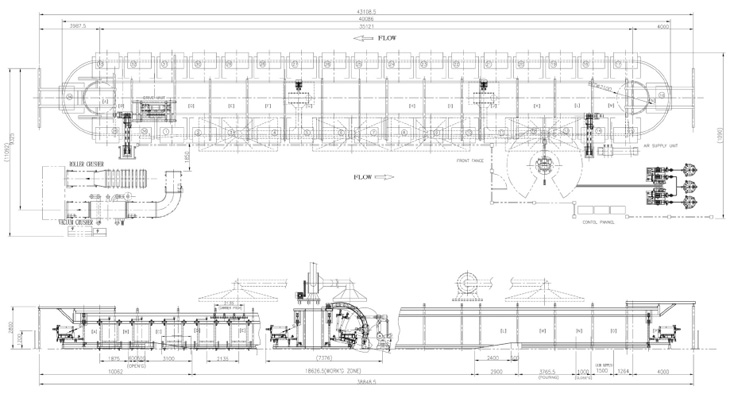

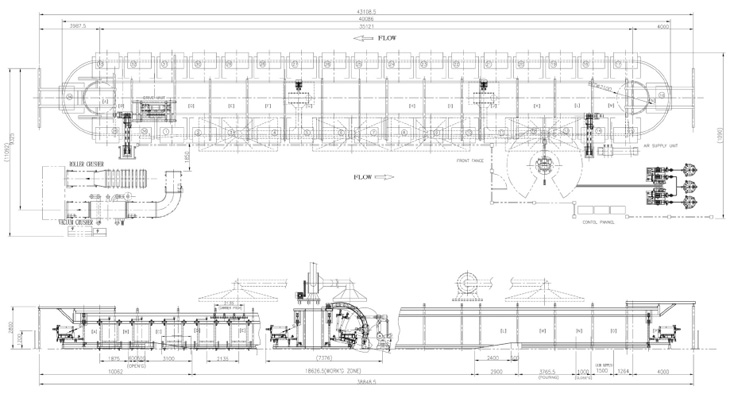

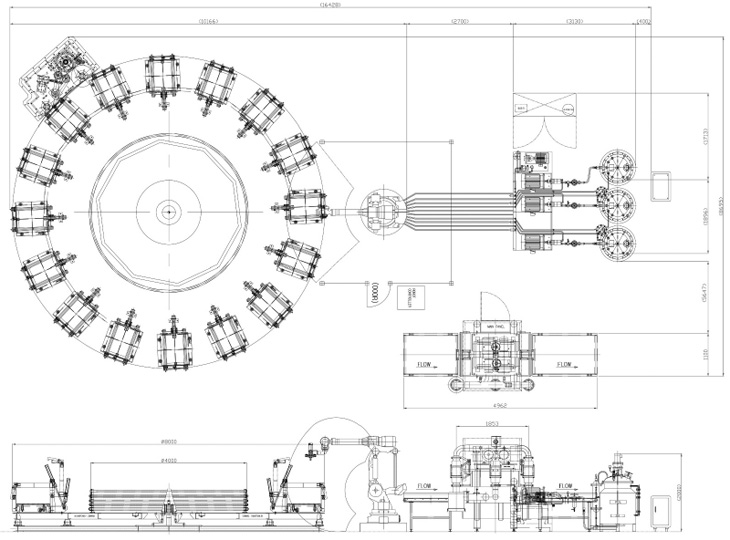

CAR SEAT LINE (Oval Conveyor)

Features

Conveyor with robot continuous line increases total output a day.

Synchronized stable robot is operated with economic cost.

different type of seats can be produced by different materials in same time. (Using by multiple mixing head)

| Specification |

| PU machine |

High pressure machine 4k Mixing Head System |

| Production method |

Continuous moving type by oval conveyor |

| PU injection |

Automatic pouring into open mould by industrial Robot |

| Mould carrier type |

1) Open and close by hydraulic

2) Open and close by mechanical unit

3) Open and close by steel guide bar |

| Mould locking/ unlocking |

Auto. locking & unlocking by air unit |

| Mould carrier |

20-36 carriers |

| Line size |

App. 30~43m(L) x 15m(W) x 5m(H) |

| Turn table speed |

App. 100-200mm/ sec, changeable type |

| The shot cycle time |

App. 10~15 sec |

| PU Curing time |

App. 4min |

| Heating unit |

4 kw/h (2carrier/ one heating unit), Hot water by electric heating |

| Seat weight |

App. Min 310g- Max 3,200g |

| Seat consists |

Front cushion and back

Rear cushion and back |

|

The consist of seat line:

High pressure PU foaming machine, 4K Mixing Head

3 sets machine tanks, 250 L

Industrial Robot

Electric control

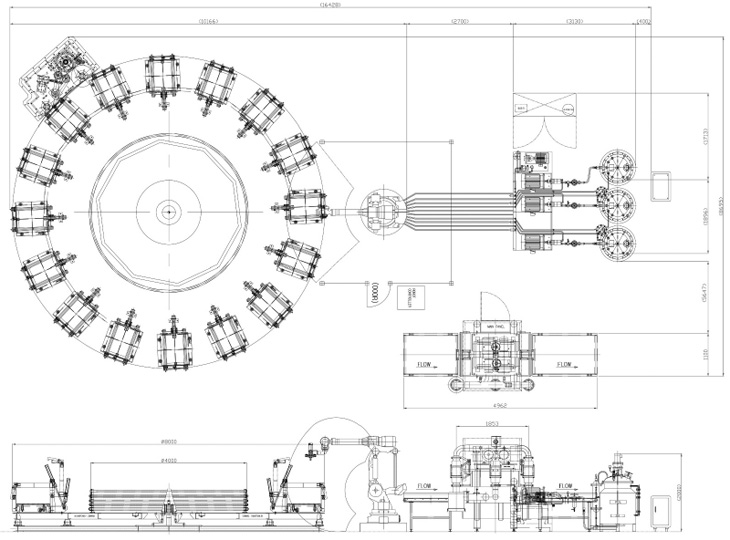

CAR SEAT LINE (Turn Table)

Features

Available to easy and quick installation

Wide range of manufacturing productions by changing mould.

| Specification |

| PU machine |

High pressure machine, 4K Mixing Head System |

| Production method |

Continuous moving type by turn table |

| Robot |

Capacity 165kg |

| PU injection |

1) Automatic pouring into open mould by industrial Robot

2) Manual pouring by worker |

| Mould carrier type |

1) Open and close by hydraulic

2) Open and close by Guide steel bar |

| Mould locking and unlocking |

Auto. locking & unlocking by air unit |

| Mould carrier |

4-24 carriers |

| Line size |

App. 4-12m(D) x 5m(H) |

| Line speed |

App. 100-200mm/ sec, changeable type |

| The shot cycle time |

App. 10-15 sec |

| Curing time |

App. 4min |

| Heating unit |

4 kw/h (2carrier/ one heating unit), Hot water by electric heating |

| Seat weight |

App. Min 310g- Max 3,200g |

| Seat consists |

Front cushion and back Rear cushion and back |

|

The consist of seat line:

High pressure PU foaming machine, 4K Mixing Head

3 sets machine tanks, 250 L

Industrial Robott

Electric control

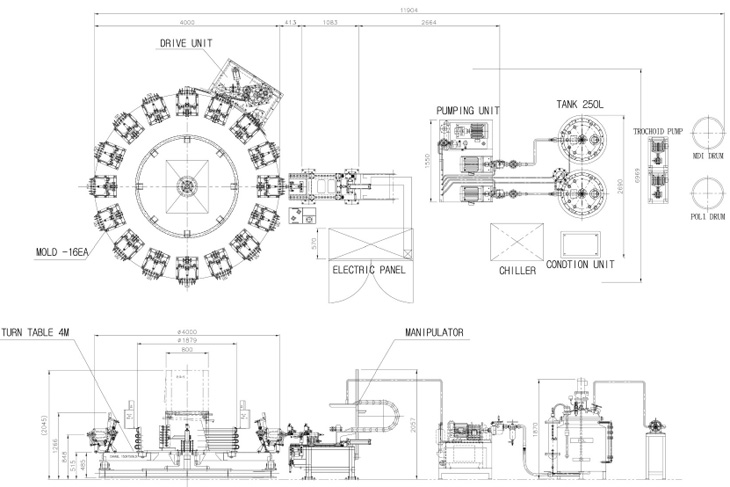

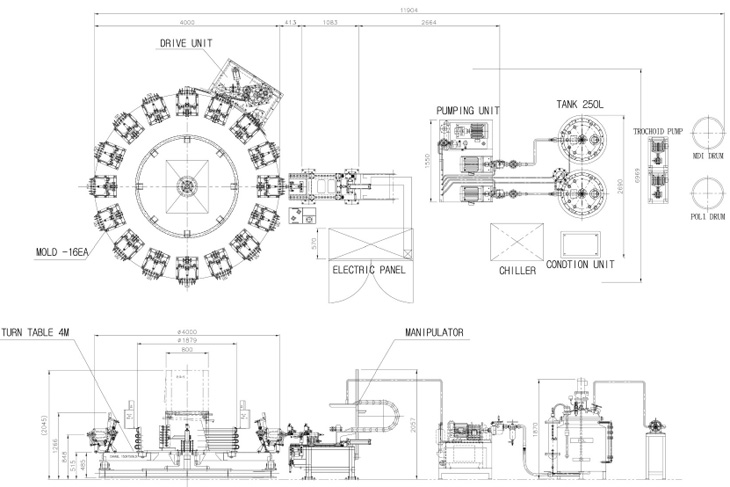

CAR HEADREST LINE

Features

High operating efficiency by single piece injection for head rest.

Easy and convenience maintenance and replacement.

Easy and stable installation with economical cost.

High compatibility among machines.

| Specification |

| PU machine |

High pressure machine, 2K Mixing Head System |

| Production method |

Stop & Go moving type by turn table |

| Product |

Foam in cover head rest |

| PU injection |

Automatic pouring into close mould by manipulator |

| Mould carrier type |

Open and close by guide steel bar

Auto. locking & unlocking by air unit |

| Mould carrier |

10-16 carriers |

| Turn table size |

App. 3.25m(D) x 2m(H) |

| Mixhead cleaning unit |

Hot water or DOP cleaning by brush turning |

| The shot cycle time |

App. 10 sec |

| Curing time |

App. 60 sec |

| Mould Heating |

Water heating by boiler |

| Head rest weight |

App. Min 150g- Max 350g |

| The required worker |

1-2 people |

| Yearly production capacity |

1 day – 8 hr x 60 min x 60 sec ÷ 10Sec = 2,880 pcs

1 month – 2880 x 25 days = 72,000 pcs

1 year – 72000 x 300 days = 21,6000,000 pcs |

|

The consist of head rest line:

High pressure PU foaming machine, 2comp. & Mixing Head DHV 1014-2K

Turn table and moulds

Manipulator with mixhead cleaning unit

Mould heating by Boiler

Mould open & close by steel guide bar

Electric control